longo toyota el monte used cars

The factory process behind metal lunch boxes often involved a series of intricate steps. First, the raw materials were sourced and cut into the appropriate sizes. Next, the metal sheets underwent printing, where vibrant colors were applied to create eye-catching designs. The pieces were then shaped, bent, and fused together, creating a sturdy construction that could withstand the rigors of daily use. Finally, a protective coating was applied to guard against rust, ensuring these lunch boxes would endure for years.

metal lunch boxes vintage factory

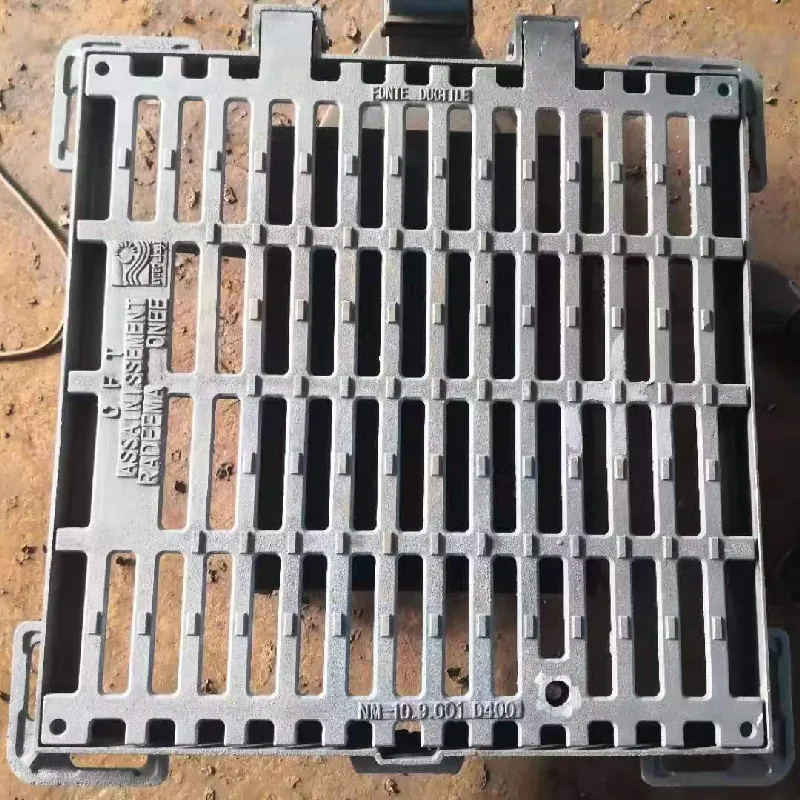

Another significant advantage of ductile iron covers and frames is their resistance to corrosion. Urban environments expose infrastructure to various corrosive elements, including chemicals from roadways, saline environments, and environmental pollutants. Ductile iron can be coated with protective finishes, such as asphalt or epoxy, to further enhance its corrosion resistance. This quality extends the life of the product substantially, reducing the need for frequent repairs or replacements and thereby resulting in cost savings for municipalities and contractors.

ductile iron cover and frame

However, the square manhole cover does come with its own set of challenges. Theoretically, if a square cover is positioned diagonally over the hole, it could fall through. This poses a risk that is inherently absent with round covers. Thus, the use of square manhole covers can be seen as a compromise—acknowledging both aesthetic and practical concerns while also embracing the complexities of urban infrastructure.

square man hole cover